Our mill section is comprised of numerous vertical mills, including 4 axis, 5 axis, and 3+2 axis machines, along with horizontal mills. We also have several super-precision lathes, swiss lathes, and 7-axis mill turning centers. Under most conditions, the mill department can reliably hold tolerances of .0002 inch, while our lathe department can hold as close as .0001 inch.

Precision Machining

- Max Mill Size – 24” x 24” x 12”

- Vertical Milling – 5 axis, 4 axis, and 3+2 axis machines

- Pallet Changers

- Super-Precision Lathes

- Swiss Lathes

- Max Turning Size is 6” Dia x 12” Long

- 7-axis Mill Turning Centers

This versatile 5-axis powerhouse precision center boasts 33 pallets and over 300 tools in its self-contained multi-pallet stacking system. With that, a tilting rotary table, self-adjusting spindle, and a myriad of other features, our programmers and operators look forward to taking on more challenges than ever before.

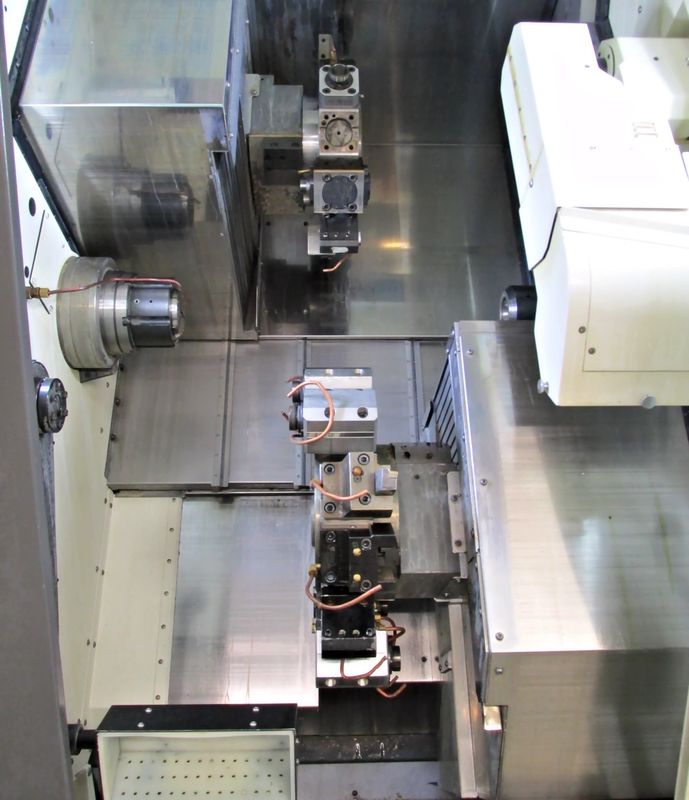

Multitasking Machine for Diversified Variable Lot-Size Production. Milling Tool Motor Power 5.5/3.7kW,

High-Performance machining with small tools. With upper and lower turret construction, simultaneous

balance cutting and other combinations available on either L or R spindles.