The Quality department is involved with every step of production. All operations from raw material to shipping must be authorized by Quality before proceeding. Both Quality personnel and Machinists are required to inspect parts regularly as they are manufactured. Inspections are documented and customers may request AS9102 FAIRs when ordering.

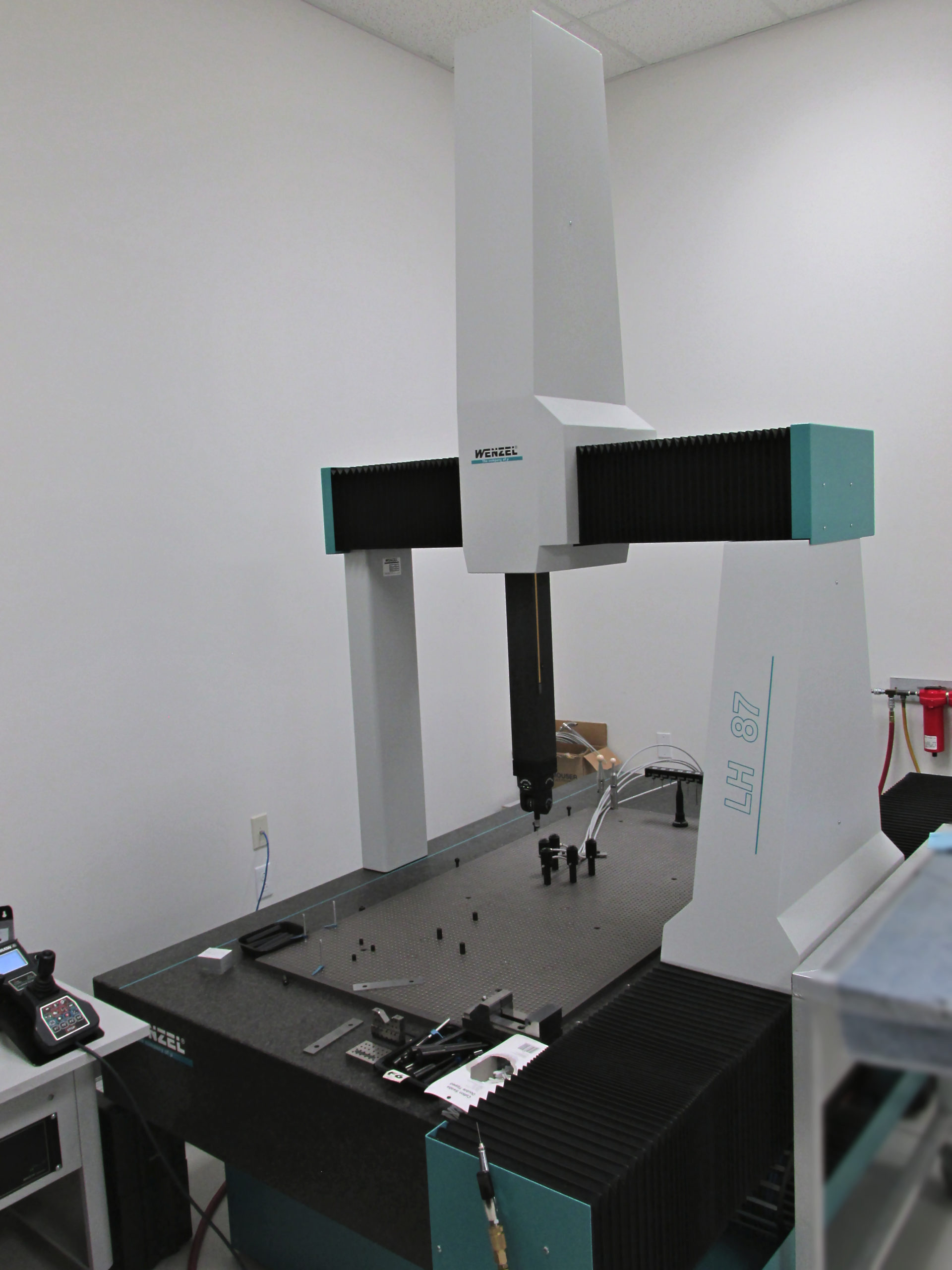

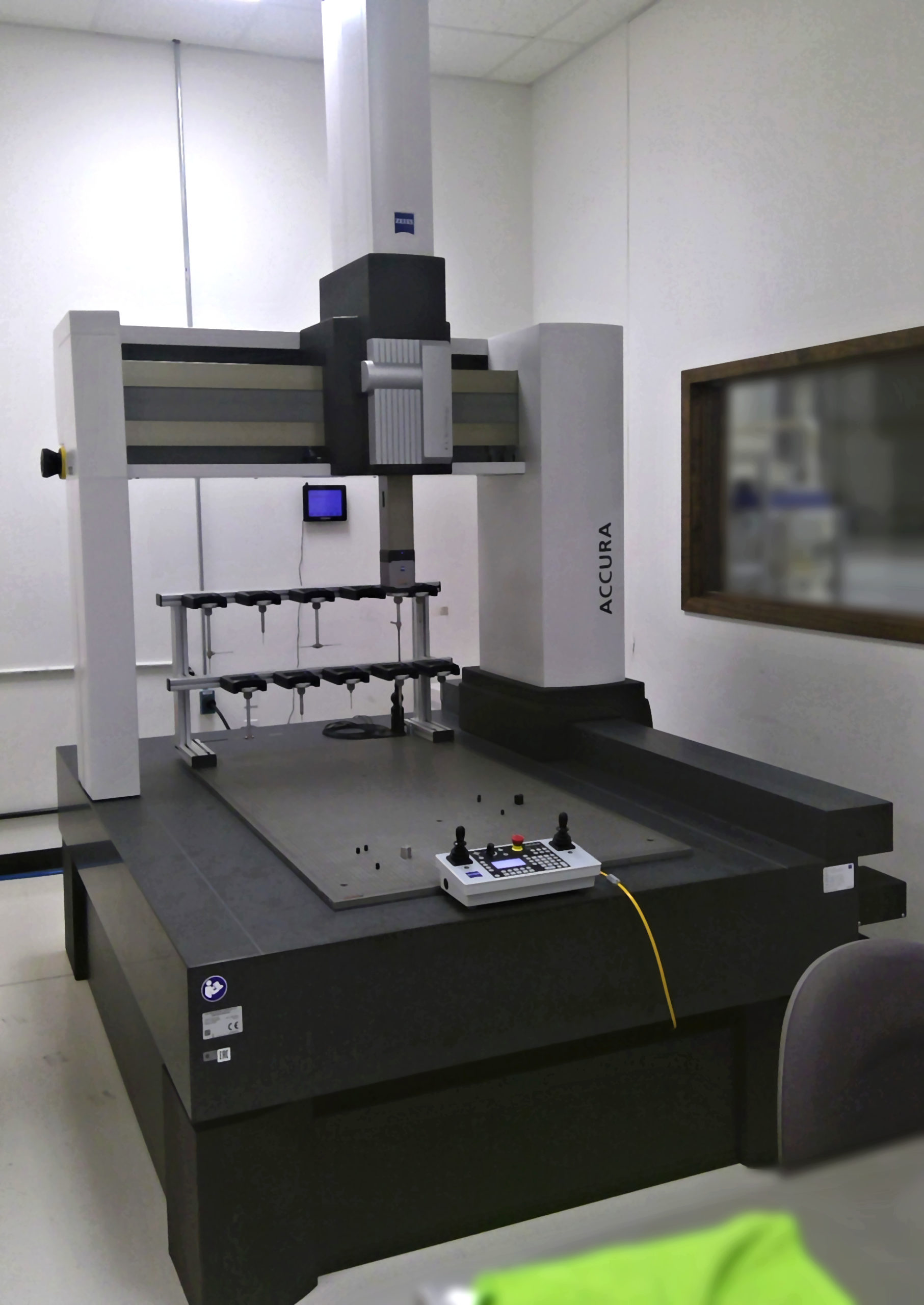

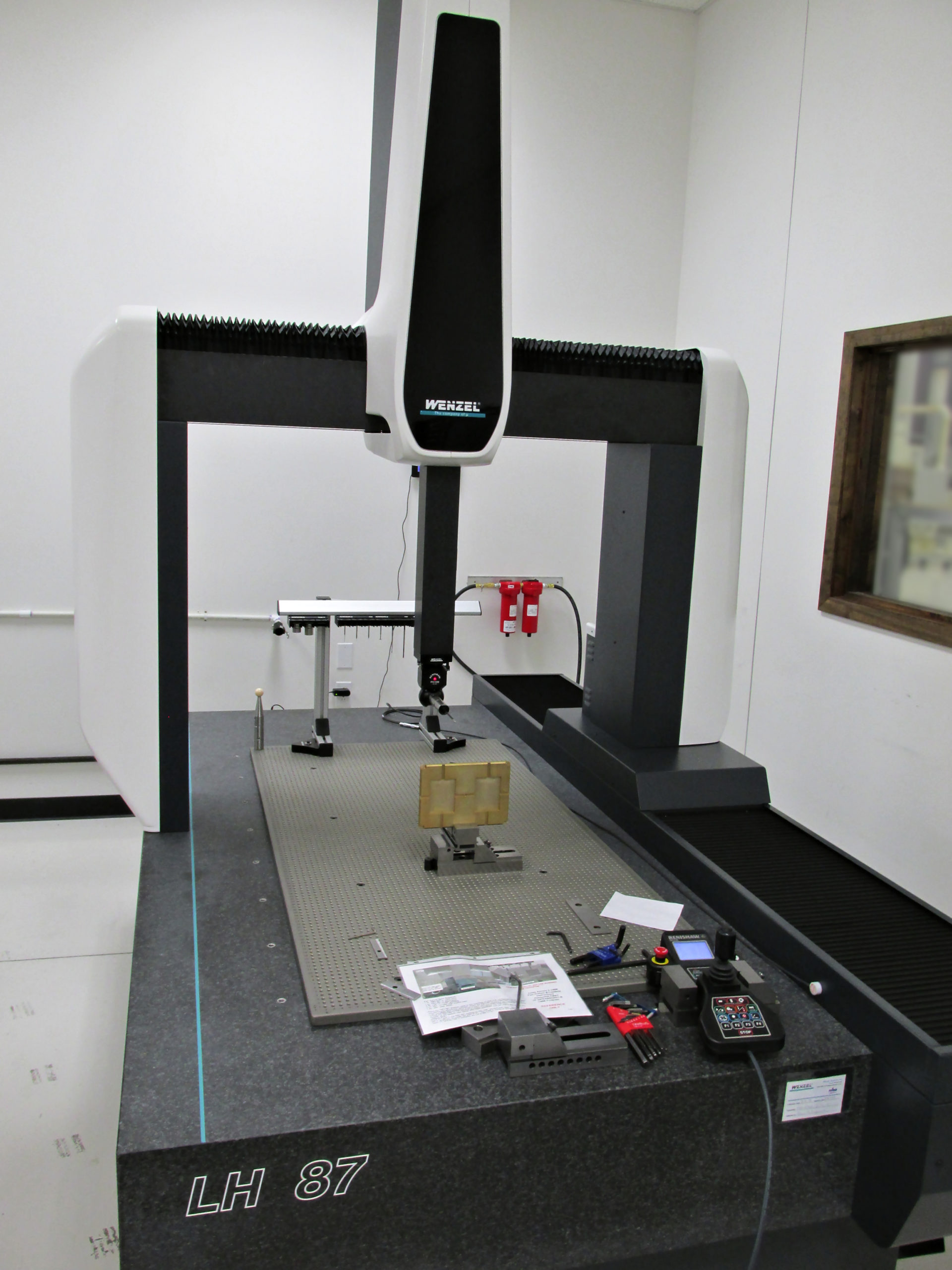

Trained Quality Inspectors periodically inspect all parts in production throughout each day. A group of inspectors is tasked with thoroughly inspecting parts prior to post-production operations, such as plating, laser etching, inserting hardware, and shipping to the customer or 3rd party.

Every tool or gage used for inspection at Natoma is calibrated on a regular schedule by a dedicated Calibration Specialist. Standards such as gage blocks and surface plates are used to calibrate most tools in-house. All standards, CNC machines, and other equipment we cannot calibrate in-house are done by trusted third parties. All traceability is logged.